Get Started With the Right Tools You Need for PCB Board Repair

Repairing a PCB board isn’t something you can do with just your hands. These boards have tiny parts, fine lines, and delicate connections. If even one part fails, the whole device can stop working. That’s why using the proper tools is key to getting the job done right.

Whether you’re fixing a broken board or replacing a damaged component, the right tools help you work faster, avoid mistakes, and get better results. This guide covers the tools you need for PCB board repair, from basic gear to more advanced items. No confusing words, no extra talk, just what you really need to get the job done.

Essential Tools You Need for PCB Board Repair

Working on a printed circuit board takes more than steady hands and patience, it demands the right tools. Without them, you risk damaging tiny components, overheating the board, or making weak connections that don’t last. Whether you’re repairing a broken connection, replacing a part, or cleaning up a bad solder joint, the right tool can make all the difference. From simple hand tools to more advanced equipment, each one plays a role in getting the job done correctly.

So, before you begin your next fix, take a look at the must-have tools you need for PCB board repair:

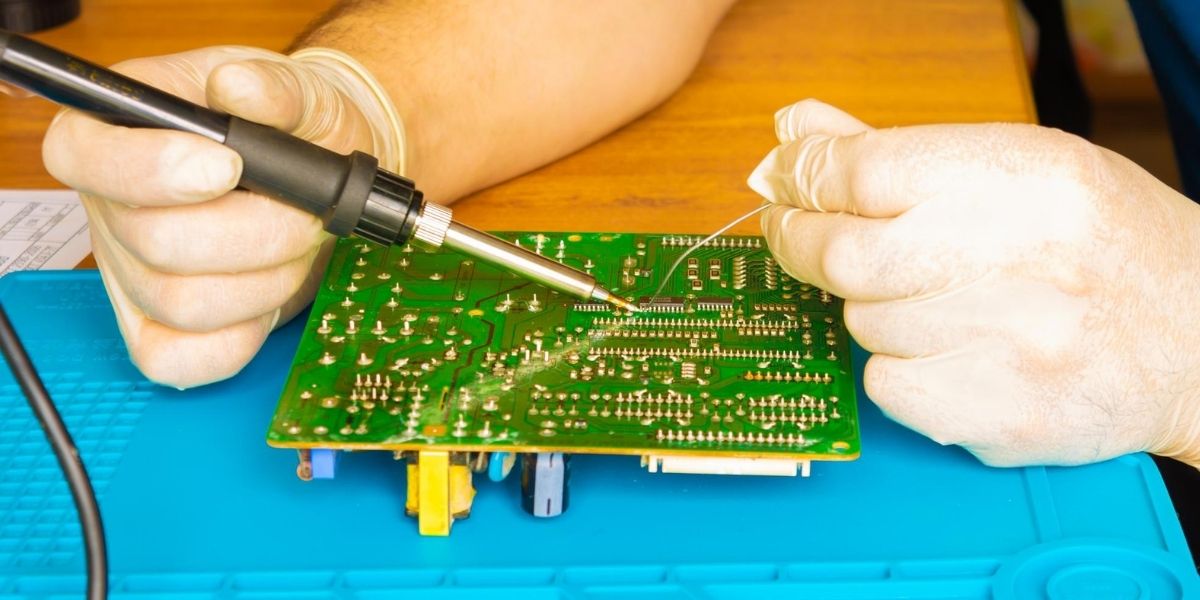

1. Soldering Iron

This is the heart of any PCB board repair kit. A soldering iron heats metal (solder) so it can flow between two parts and form a solid connection.

Why it matters:

Most PCB problems involve broken or weak solder joints. A quality soldering iron helps you reattach components or add new ones.

What to look for:

- Adjustable temperature

- Fine tip for small parts

- Quick heat-up time

A soldering station with a stand and temperature control is a smart pick. Brands like Weller and Hakko are solid options, but Horizon Elect Devices also offers reliable, budget-friendly choices.

2. Solder

Solder is the metal wire that melts to connect components to the board. It’s usually made from a mix of tin and lead, or lead-free alloys for safer use.

Tip: Use thin solder (0.5mm to 0.7mm) for precision. Rosin-core solder helps clean the joint as it melts.

3. Desoldering Pump

Mistakes happen. Sometimes you need to remove a part or fix a bad joint. A desoldering pump, also called a solder sucker, pulls melted solder away from the board.

Why you need it: It keeps your board clean and prevents damage when removing parts.

4. Desoldering Braid

This is a thin copper wire braid that absorbs melted solder when placed over a joint and heated. It’s perfect for cleaning up leftover solder.

Why it’s helpful:

- Reaches small, tight spots

- Leaves a clean surface

- Works with little heat

Use it after removing a part to prepare for new soldering.

5. Tweezers

Many parts on a PCB are tiny. Trying to hold them with your fingers can damage them or make you drop them.

Precision tweezers help you:

- Pick up small parts

- Hold components in place

- Avoid burns

Look for anti-static tweezers made for electronics. They protect your parts from static electricity, which can ruin sensitive chips.

6. Magnifying Glass or Microscope

It’s hard to fix what you can’t see. Some problems on a PCB are almost invisible to the naked eye.

A magnifying glass or a digital microscope helps you:

- Spot broken solder joints

- Find cracks in traces

- Read part numbers

A headband magnifier leaves your hands free, while digital microscopes let you view and even take pictures.

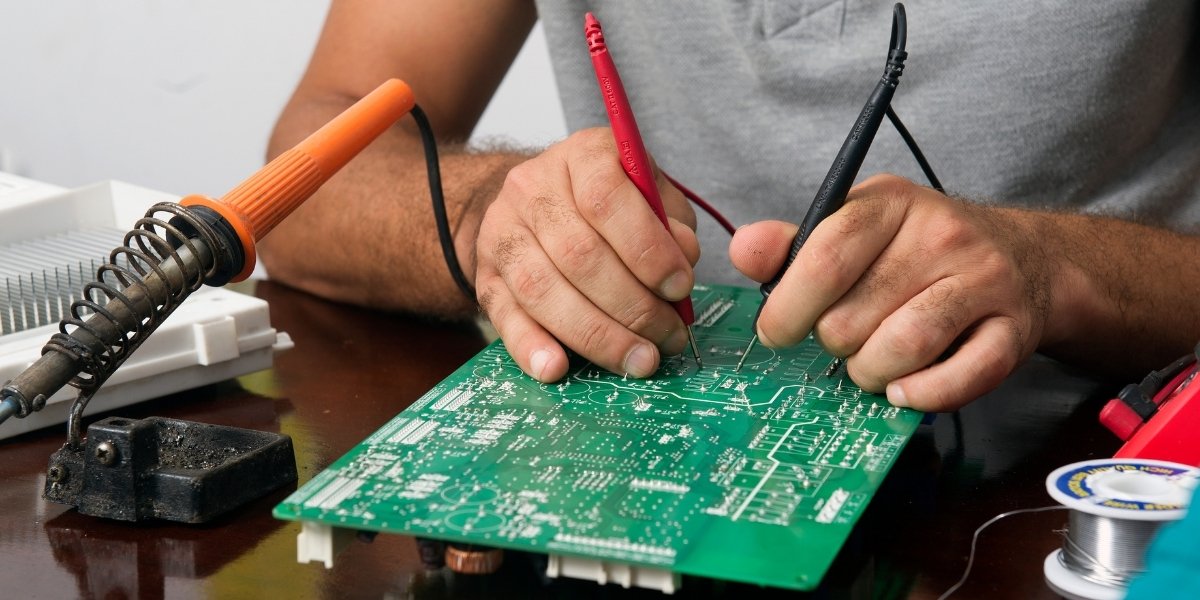

7. Multimeter

A multimeter checks if a part or connection is working. It measures voltage, current, and resistance. It’s one of the best tools to find broken parts or short circuits.

Why it’s important:

- Test power lines and components

- Check if fuses or resistors work

- Find shorted paths or bad connections

Choose one with auto-range and continuity beep for easier use.

8. Hot Air Rework Station

This tool blows hot air to melt solder without touching the board. It’s great for working with surface-mount components (SMDs) that are too small for regular soldering.

When to use it:

- Replacing SMD chips

- Fixing lifted pads

- Removing stubborn components

You can adjust the temperature and airflow. Practice is key, as too much heat can damage the board.

9. PCB Holder or Clamp

When soldering or desoldering, it helps to keep the board still. A PCB holder or clamp grips your board so you can work with both hands.

What to look for:

- Adjustable arms

- Non-slip base

- Fits different board sizes

Some holders come with built-in lights or magnifiers.

10. Flux

Flux is a chemical used before soldering. It cleans metal surfaces and helps solder stick better.

Benefits:

- Prevents oxidation

- Makes solder flow smoothly

- Reduces solder balls and bridges

Flux pens are easy to apply. Just use a small amount before soldering.

11. Cleaning Tools

After soldering, the board can have residue or debris. Cleaning is not just for looks, it helps your board last longer and perform better.

Useful cleaning items:

- Isopropyl alcohol (90% or higher)

- Soft brush (like a toothbrush)

- Lint-free cloths or wipes

These tools remove flux residue and dust. Clean boards also make it easier to spot damage later.

12. Heat Gun

While not a must-have for beginners, a heat gun can help for larger components or when repairing damaged traces.

Use it for:

- Reflowing solder on big parts

- Removing stubborn adhesives

- Softening glue on connectors

Be careful with the temperature to avoid melting plastic parts.

13. PCB Repair Kit

These kits include:

- Copper pads

- Circuit traces

- Epoxy Cutting tools

They’re helpful when you need to fix broken tracks or pads on the board. This often happens when a part is removed forcefully or the board gets burned.

If you’re working on high-value boards, it’s good to have one on hand.

14. Anti-Static Wrist Strap

Static electricity can destroy some electronic parts before you even touch them. An anti-static wrist strap helps release any built-up static from your body, keeping your electronic parts safe while you work.

How to use:

- Strap it to your wrist

- Clip the other end to a grounded surface

It’s cheap but important. Many professionals won’t work on a board without one.

Why Having the Right Tools Matters

PCB repair isn’t just about skill. Without the right tools, even simple fixes can go wrong. A wrong move with a cheap soldering iron can burn a trace. Poor lighting can make you miss a bad joint. A shaky hand without tweezers can knock other parts loose.

That’s why techs trust brands like Horizon Elect Devices. They provide tools that are reliable, easy to use, and affordable. Whether you’re a hobbyist or starting a repair business, their tool range supports all kinds of PCB repair work.