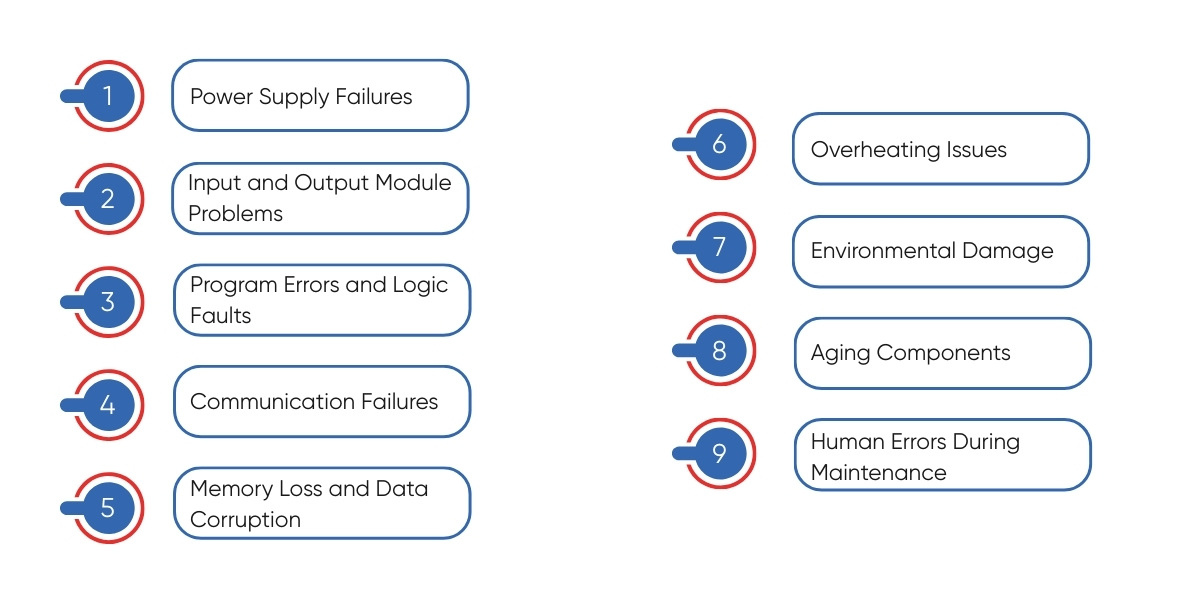

Key PLC Problems and Solutions That Affect Productivity

Programmable Logic Controllers, commonly known as PLCs, are the backbone of many industrial systems. From manufacturing plants to processing units, these controllers manage operations that must run without interruption. Even a small issue in a PLC can lead to downtime, production loss, or safety risks. Understanding common PLC problems and solutions helps industries maintain stable operations and avoid unexpected failures.

This blog explains the most common PLC issues, why they occur, and provides practical ways to fix or prevent them, ensuring your systems continue to run smoothly.

Common PLC Problems and Solutions in Industrial Systems

PLCs are designed for harsh environments, but they still encounter challenges. Electrical noise, poor maintenance, harsh conditions, and ageing components are some of the most common reasons for failure. In many cases, problems do not appear suddenly. They develop slowly and show warning signs that are often ignored.

Regular checks and proper handling reduce risks, but knowing how to identify problems early is just as important.

Power Supply Failures

Power-related issues are one of the leading causes of PLC malfunctions. Unstable voltage, frequent power fluctuations, sudden outages, or improper grounding can directly affect the internal components of a PLC. These conditions may cause random shutdowns, unexpected controller restarts, corrupted programs, or complete system failure. Over time, repeated power stress weakens power modules and shortens the overall lifespan of the controller.

Solutions:

- Use a stable and regulated power supply suitable for industrial environments.

- Ensure proper grounding to avoid electrical noise and interference.

- Install surge protectors to protect PLCs from voltage spikes caused by lightning or heavy machinery.

- Use uninterruptible power supplies to maintain operation during short power interruptions.

- Inspect power modules periodically to identify early signs of wear, overheating, or damage.

Input and Output Module Problems

Input and output modules act as the communication bridge between the PLC and field devices such as sensors, motors, and actuators. Loose wiring, damaged terminals, or incorrect connections can cause false signals or loss of communication. As a result, machines may behave unpredictably, stop mid-operation, or fail to respond to control commands.

Solutions:

- Conduct regular checks on all wiring connections to ensure they are secure.

- Replace damaged or faulty I/O modules immediately to prevent incorrect data transfer.

- Use proper cable management techniques to reduce strain on terminals.

- Clearly label all cables and modules to simplify future inspections and reduce troubleshooting time.

Program Errors and Logic Faults

Programming errors are a common source of PLC issues, especially after system upgrades or logic changes, making timely PLC repair essential to fix incorrect instructions, missing interlocks, or poorly configured timers that cause unexpected machine behaviour or process interruptions.

Solutions:

- Test new or modified programs in a controlled environment before deploying them.

- Maintain backup copies of all PLC programs to allow quick restoration if issues occur.

- Use structured programming methods to improve readability and reduce mistakes.

- Document all changes clearly so future troubleshooting becomes easier.

Communication Failures

PLCs rely on communication networks to exchange data with HMIs, SCADA systems, and other controllers. Communication problems may arise due to damaged cables, incorrect network settings, or excessive data traffic. When communication fails, operators lose visibility and control, which can affect safety and productivity.

Solutions:

- Inspect communication cables and connectors for physical damage or wear.

- Verify network parameters such as IP addresses, baud rates, and protocols.

- Reduce network load by optimising data transfer settings.

- Use industrial-grade communication components designed for harsh environments.

Memory Loss and Data Corruption

Memory loss can occur when backup batteries fail or when PLCs experience sudden power loss. This may result in the loss of stored programs, settings, or production data. Such incidents can stop operations instantly and require time-consuming system recovery.

Solutions:

- Replace backup batteries according to manufacturer recommendations.

- Store program backups on external devices and verify them regularly.

- Follow proper shutdown procedures to protect stored data.

- Monitor battery health during routine maintenance checks.

Overheating Issues

PLCs generate heat during normal operation. Poor ventilation, dust buildup, or high ambient temperatures can cause excessive heat accumulation inside control panels. Overheating reduces component efficiency and increases the risk of sudden failure.

Solutions:

- Ensure adequate airflow within control panels.

- Clean dust and debris from enclosures on a regular basis.

- Install cooling fans or air conditioning units where temperature levels are high.

- Monitor panel temperatures to detect overheating early.

Environmental Damage

Harsh industrial environments expose PLCs to moisture, vibration, chemicals, and dust. Over time, these factors damage internal circuits, connectors, and terminals, leading to unreliable performance.

Solutions:

- Use sealed enclosures suitable for industrial conditions.

- Protect PLCs from water, oil, and corrosive substances.

- Secure mounting to minimise vibration impact.

- Inspect enclosures regularly for signs of environmental damage.

Aging Components

As PLC systems age, internal components such as capacitors, relays, and connectors begin to degrade. This gradual wear often leads to intermittent faults before complete failure occurs.

Solutions:

- Plan preventive replacement of ageing components.

- Avoid waiting for total failure before taking action.

- Seek professional support from specialists in industrial electronics repair to extend system life safely.

Human Errors During Maintenance

Mistakes during maintenance activities, such as incorrect wiring or improper settings, can create new PLC issues. These errors are often unintentional but can result in significant downtime.

Solutions:

- Follow documented maintenance procedures consistently.

- Use checklists to ensure all steps are completed correctly.

- Verify system settings before restarting operations.

- Provide regular training for maintenance staff to reduce errors and improve efficiency.

Ensuring Long-Term Reliability of PLC Systems

PLCs play a critical role in modern industrial operations, and even minor issues can disrupt entire processes. Understanding plc problems and solutions helps industries respond quickly, reduce downtime, and avoid costly breakdowns. With proper care, regular maintenance, and timely intervention, PLC systems can continue to perform reliably for many years.

Addressing problems at an early stage and choosing expert support for industrial electronics repair in Dubai ensures systems are restored safely and efficiently. Trusted service providers like Horizon Elect Devices help businesses protect their equipment, extend system life, and maintain uninterrupted operations in demanding industrial environments.