Industrial Automation and Control Explained for Modern Industries

Walk into any modern factory today, and one thing becomes clear very quickly. Very little is left to chance. Machines communicate with each other, processes follow a clear rhythm, and production moves forward with minimal interruption. This shift did not happen overnight. It is the result of steady progress in industrial automation and control, which has quietly reshaped how businesses operate.

For many companies, automation is no longer about replacing people. It is about creating stability, accuracy, and predictability in environments where even small mistakes can be costly.

The Role of Industrial Automation and Control

Industrial automation and control are the backbone of modern industrial operations. It helps businesses manage complex processes in a structured and reliable way. By combining machines, data, and human supervision, automation creates stable workflows that are easier to monitor and control. Below are the core elements that make these systems work together smoothly.

Sensors

- Collect real-time data related to temperature, pressure, speed, flow, and other operating conditions.

- Provide accurate input that allows systems to respond to changes instantly.

- Support continuous monitoring and early fault detection.

Sensors act as the data source for the entire automation setup. Without consistent data collection, process control becomes unreliable.

Controllers

- Process incoming data based on programmed logic.

- Decide how machines and systems should respond to specific conditions.

- Maintain process stability by following predefined rules.

Controllers coordinate the system’s behaviour and ensure operations stay within safe and efficient limits.

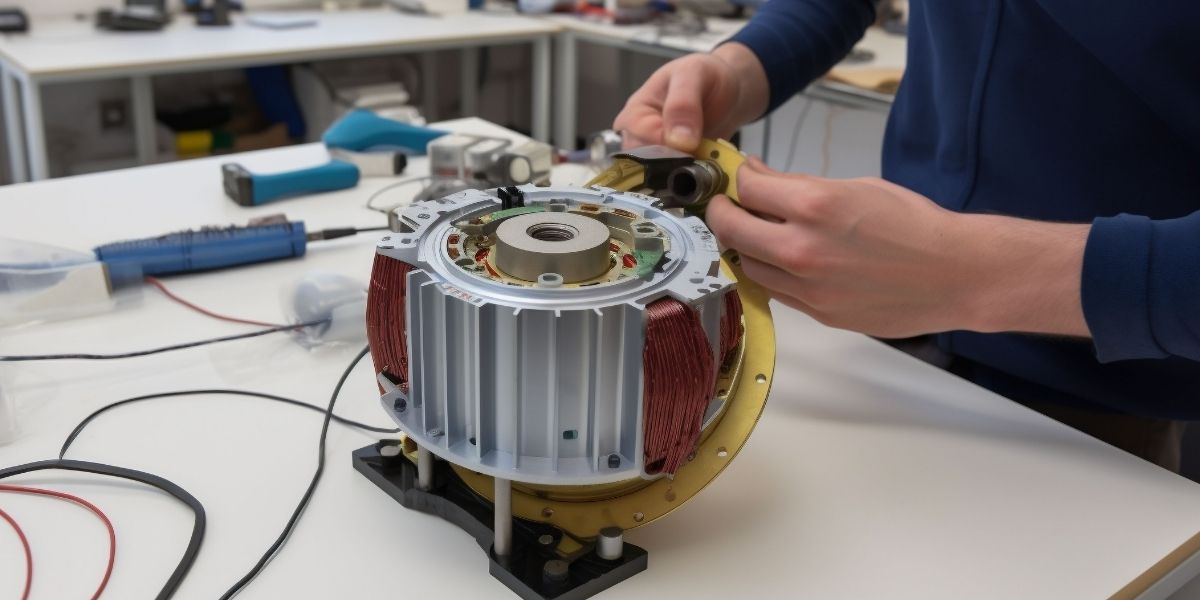

Actuators

- Convert control signals into physical movement or mechanical action.

- Handle functions such as motion control, positioning, and adjustments.

- Execute decisions made by controllers accurately.

Actuators turn system decisions into real-world actions that keep production moving.

Human-Machine Interfaces (HMI)

- Display system status, alerts, and performance data.

- Allow operators to monitor and adjust processes when needed.

- Improve visibility and control across operations.

HMIs ensure humans remain actively involved in supervising automated systems.

Communication Networks

- Connect all system components for seamless data exchange.

- Enable real-time coordination between devices.

- Support system responsiveness and synchronisation.

Reliable communication keeps automation tools stable and efficient.

Software Platforms

- Manage monitoring, scheduling, and system optimisation.

- Analyse operational data for better decision-making.

- Support long-term system performance and scalability.

Software adds intelligence and structure to industrial automation environments.

Key Benefits of Industrial Automation for Businesses

Industrial automation supports daily operations in ways that go far beyond speed and convenience. For modern businesses, it creates a structured working environment where processes remain stable, predictable, and efficient. Below are some of the most important benefits that automation brings to industrial operations, explained in practical terms.

Consistent Output

One of the biggest challenges in manual production is maintaining the same level of quality across every shift and batch. Human performance can change based on fatigue, experience, or workload. Automated systems remove this inconsistency by following predefined instructions every single time.

Once a process is programmed correctly, machines perform tasks with the same precision regardless of time or volume. This consistency helps businesses maintain uniform product quality, which is especially important in industries where even small variations can lead to rejections or customer complaints. Over time, consistent output strengthens brand reliability and builds customer trust.

Automation also simplifies quality control. When processes remain stable, identifying defects or deviations becomes easier, allowing teams to address issues quickly without disrupting production.

Reduced Human Error

Human error is a natural part of manual work, especially when tasks are repetitive or time-sensitive. Simple mistakes such as incorrect measurements, skipped steps, or delayed responses can cause production delays and material waste.

Automated systems significantly reduce these risks by handling repetitive tasks with programmed accuracy. Machines do not lose focus or get tired, which means critical steps are executed exactly as planned. This reduces scrap, rework, and unexpected downtime.

By minimising errors, businesses can operate more smoothly and predictably. Employees also experience less stress, as they are no longer pressured to maintain extreme accuracy during long or demanding shifts.

Better Use of Manpower

Automation does not remove the need for people. Instead, it changes how human effort is used. When machines handle routine and repetitive tasks, employees can focus on areas where human judgment and experience matter most.

Workers can move into roles involving supervision, system monitoring, maintenance planning, and process improvement. This shift not only improves productivity but also increases job satisfaction, as employees engage in more meaningful work rather than repetitive manual labour.

From a management perspective, this better use of manpower leads to a more skilled workforce. Teams become problem solvers instead of task repeaters, which adds long-term value to the organisation.

Improved Workplace Safety

Industrial environments often involve risks such as heavy machinery, high temperatures, electrical systems, and hazardous materials. Manual handling of such tasks increases the likelihood of accidents and injuries.

Automation helps create safer workplaces by allowing machines to take on high-risk operations. Tasks like heavy lifting, precise cutting, or exposure to extreme conditions can be handled automatically, keeping workers at a safe distance.

Control systems also play an important role in safety. Automated monitoring detects abnormal conditions early and triggers alerts or shutdowns before accidents occur. This proactive approach helps businesses maintain compliance with safety regulations while protecting their workforce.

A safer workplace also reduces downtime caused by accidents and improves employee morale, creating a more stable working environment.

Lower Long-Term Operating Costs

While automation requires an initial investment, its long-term financial benefits are significant. Automated systems help reduce waste by maintaining accurate control over materials and processes. Fewer errors mean less rework, lower scrap rates, and better use of raw materials.

Automation also reduces unexpected equipment failures. With proper monitoring and control, issues are detected early, allowing maintenance teams to act before major breakdowns occur. This prevents costly emergency repairs and long production stoppages.

Energy efficiency is another cost-saving factor. Automated systems optimise machine usage and reduce unnecessary energy consumption. Over time, these savings contribute to lower operational expenses and improved profitability.

When businesses view automation as a long-term strategy rather than a quick upgrade, the return on investment becomes clear through stable performance and controlled costs.

Overall Business Impact

Together, these benefits create a strong foundation for sustainable growth. Consistency improves product quality, reduces errors, protects resources, better manpower use strengthens teams, improves safety, protects people, and lowers costs, improving financial health.

Automation allows businesses to operate with confidence in demanding markets. Instead of reacting to daily challenges, companies can focus on planning, innovation, and customer satisfaction. This shift is what makes industrial automation a key driver for modern business success.

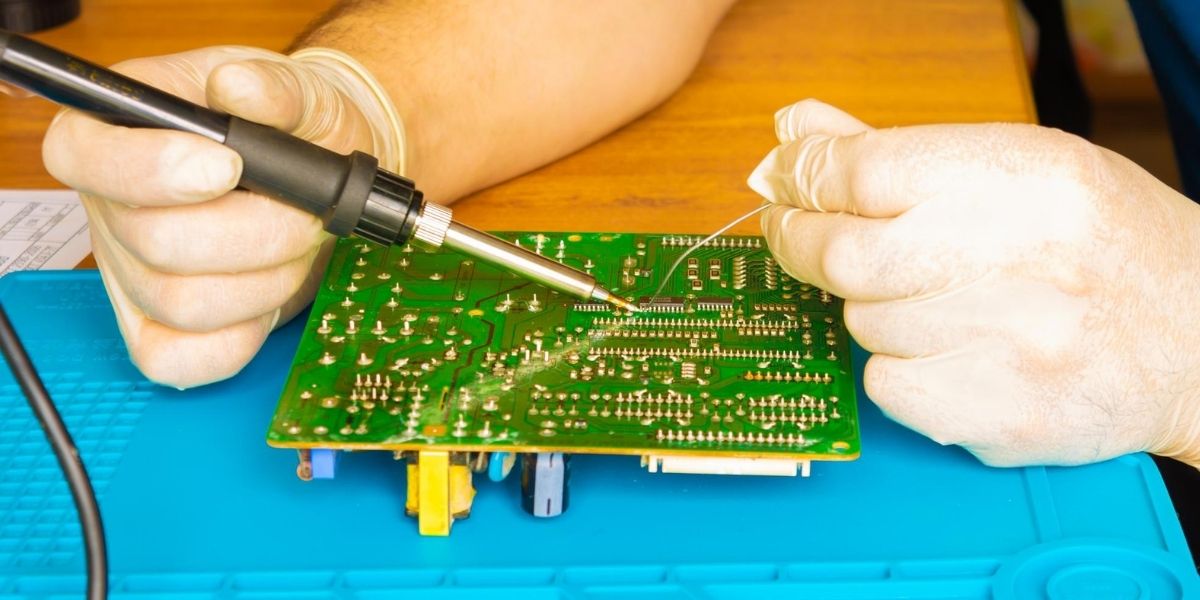

Supporting Long-Term System Reliability

Businesses that invest in automation must also focus on long-term reliability. Preventive maintenance programs, system audits, and performance monitoring help identify issues before they escalate. This proactive approach ensures steady output and protects equipment investments.

Companies like Horizon Elect Devices support industries by offering industrial electronics repair and technical solutions that keep automation systems running efficiently. Their expertise helps businesses maintain operational stability even as systems grow more complex.