Flow Meter Repair and Calibration Guide for Industries

Flow meters are essential tools in industries that require accurate measurement of liquid or gas flow. Whether it’s a water treatment plant, oil and gas facility, food processing unit, or manufacturing site, these devices ensure processes run smoothly and efficiently. Over time, however, flow meters can lose accuracy or develop faults, making repair and calibration a necessary part of their maintenance.

This guide explains everything you need to know about flow meter repair and calibration, including when it’s needed, how it’s done, and why working with the right experts is essential.

How to Know If Your Flow Meter Needs Repair and Calibration?

Flow meters are designed to deliver accurate, consistent measurements for years, but like any piece of industrial equipment, they can develop issues over time. The challenge is that many of these problems start small and gradually worsen, making it easy to overlook the early warning signs. Recognizing these indicators early can save you from costly downtime, product waste, or even safety risks.

Below are some of the most common signs that your flow meter needs professional servicing

1. Inconsistent Readings

If the meter shows fluctuations in flow rates without any real changes in the system, it could be a sign of trouble. Inconsistencies often stem from issues with the sensors, signal interference, or internal wear. Left unchecked, these false readings can lead to incorrect decision-making in production or process control.

2. Reduced Output Accuracy

When production data no longer aligns with expected performance or quality standards, calibration may be off. Even small measurement errors can have a big impact in industries where precise quantities are critical. A professional

instruments repair service can quickly restore accuracy and reliability.

3. Slow Response Time

A healthy flow meter should provide near-instant feedback. If there’s a noticeable delay in the readings, the problem could be related to clogged sensors, electrical faults, or internal component wear. Slow responses can cause inefficiencies in process adjustments, leading to wasted resources.

4. Physical Damage

Visible signs of wear, such as cracks, dents, rust, or corrosion on the housing, should never be ignored. Damage to the outer casing can allow moisture, dust, or chemicals to reach the internal electronics, leading to more severe failures.

5. Frequent Alarms or System Errors

If the flow meter is triggering alarms more often than usual or generating error codes, it’s usually a symptom of deeper electrical or mechanical issues. These problems require immediate attention to prevent complete system failure.

Step-by-Step Flow Meter Repair and Calibration Process

When your operations rely on precise measurements, sending a faulty meter to a professional flow meter repair service can mean the difference between costly downtime and a quick recovery. The process is not just about fixing what’s broken’s about restoring the unit’s performance to its original factory specifications, ensuring long-term reliability. Here’s a closer look at how the service is typically carried out from start to finish.

1. Initial Inspection and Assessment

The process begins the moment the flow meter arrives at the service center. Experienced technicians start with a visual inspection to identify any signs of external damage, such as cracks, corrosion, or worn seals. These early observations can give strong clues about possible internal issues.

In addition to the physical check, the technician will review the meter’s operational history. This includes

- Reports of unusual readings

- Frequency of alarms or error messages

- Environmental conditions it operates under (temperature, humidity, exposure to chemicals)

- Previous maintenance records

The goal here is to pinpoint the root cause of the problem rather than just treating the symptoms. By understanding the operating environment and history, technicians can tailor the repair process for the best results.

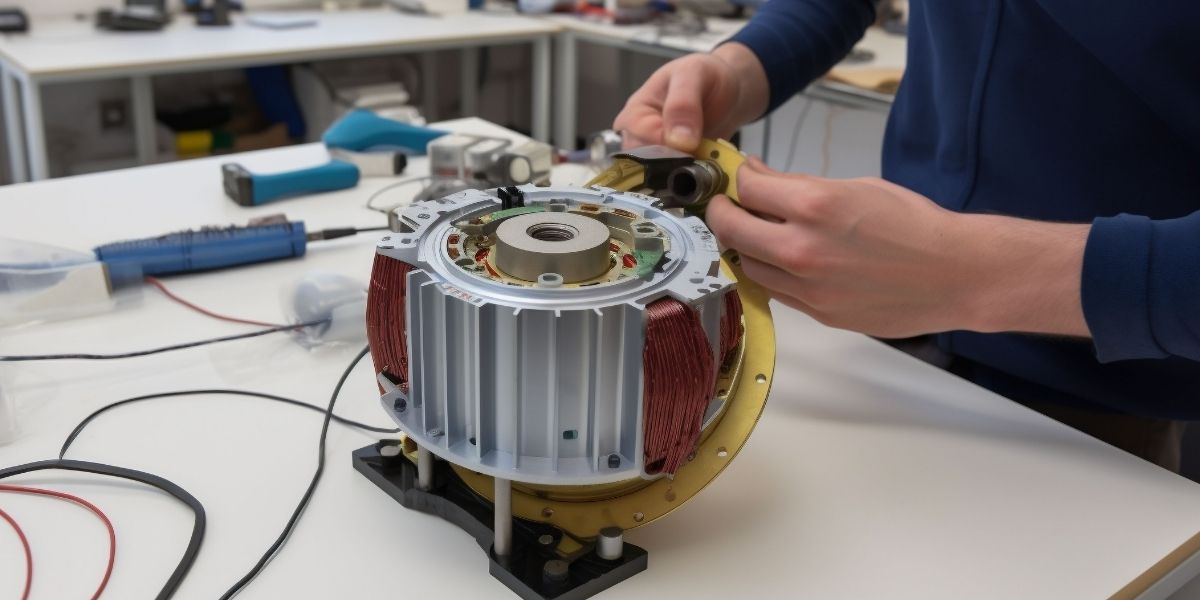

2. Disassembly and Cleaning

Once the initial inspection is complete, the flow meter is carefully disassembled. Precision is key here; technicians document the process, often taking photos, to ensure each part is reassembled exactly as it should be.

Over time, flow meters can accumulate debris, mineral scale, or chemical deposits that affect performance. Cleaning removes these contaminants, which can obstruct moving parts or interfere with sensor accuracy. Specialized cleaning agents and ultrasonic cleaning tanks may be used to gently but effectively restore each component without causing further wear.

This stage is crucial because even if no mechanical parts are damaged, buildup inside the meter can lead to inaccurate readings. Proper cleaning can sometimes bring a meter back into acceptable accuracy ranges before deeper repairs are even necessary.

3. Component Testing

With the unit stripped down and cleaned, technicians move on to testing each individual part. This may include

- Sensors – Checked for proper signal output and responsiveness.

- Rotors or Turbine Blades – Examined for wear, imbalance, or deformation.

- Magnets – Tested for magnetic strength and alignment.

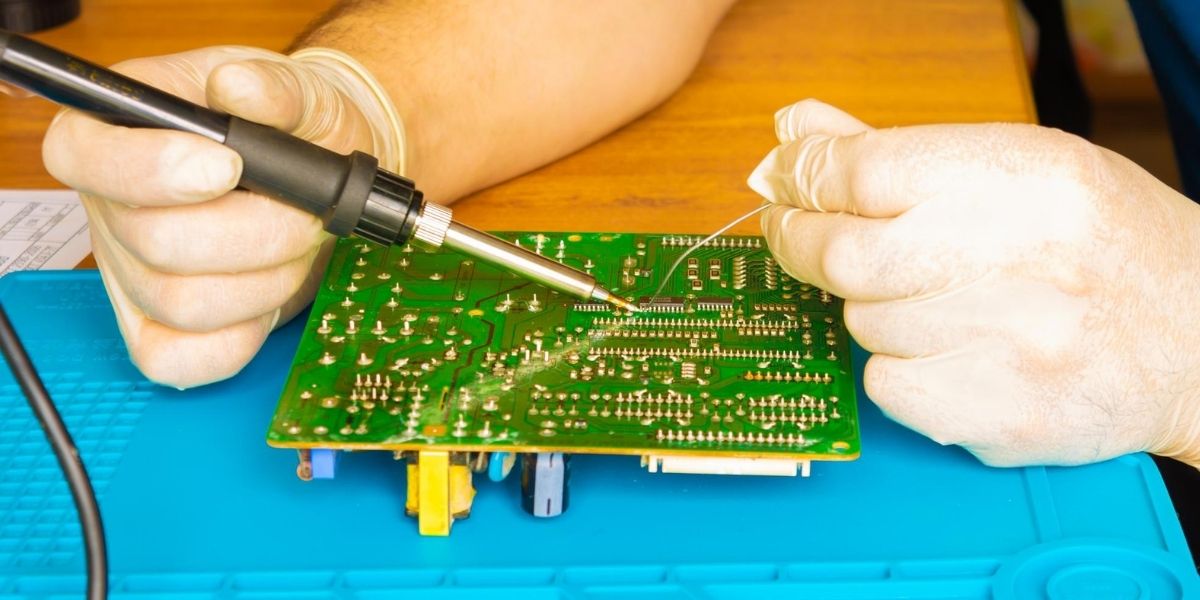

- Electronic Boards – Checked for burnt components, loose connections, or moisture damage.

Advanced diagnostic equipment is used to simulate operating conditions and monitor each part’s performance. If a component is faulty, it is either repaired on-site or replaced with genuine manufacturer-approved parts to ensure compatibility and durability.

4. Calibration

After repairs, the unit is ready for calibration. This step is all about restoring accuracy. Calibration involves comparing the flow meter’s readings against a known, traceable standard often set by national or international measurement bodies.

Using a controlled test setup, technicians pass a precise flow of liquid or gas through the meter and record its readings. Adjustments are then made so the meter’s output matches the standard within acceptable tolerances. This process may need to be repeated multiple times to ensure accuracy across different flow ranges.

Calibration is more than a formality; in many industries, it’s a compliance requirement for safety, quality control, and regulatory reporting. Without it, even a fully repaired meter may still provide unreliable data.

5. Reassembly and Final Testing

Once the meter has been cleaned, repaired, and calibrated, it is carefully reassembled. Each seal, fastener, and housing is inspected to ensure no leaks or mechanical weaknesses are introduced during the rebuild.

The unit is then subjected to final operational testing under simulated working conditions. This step verifies that

- The meter is mechanically sound

- Readings are accurate across the expected operating range

- The electronics are communicating correctly with any connected systems

This double-check ensures the repair isn’t just temporary but will hold up in real-world usage.

Keeping Your Flow Meters Accurate and Reliable

Keeping your flow meters in top condition is vital for accurate measurements and smooth operations. Choosing a trusted

industrial electronics repair provider ensures both mechanical and electronic components are restored to peak performance. Horizon Elect Devices offers expert flow meter servicing with advanced tools and skilled technicians, helping you avoid downtime and costly errors. By partnering with a reliable specialist, you can extend equipment life, maintain compliance, and achieve consistent performance in every critical process.