Complete List of Best Automation Tools for Modern Electricians

As technology continues to advance, electricians are no longer limited to traditional tools like screwdrivers, multimeters, and pliers. The rise of automation in electrical systems has transformed the industry, requiring professionals to adapt by integrating modern automation tools into their work. In 2026, the demand for smart, efficient, and reliable equipment is higher than ever. Whether you are involved in residential, commercial, or industrial projects, having the right set of automation tools can significantly enhance your productivity, accuracy, and safety.

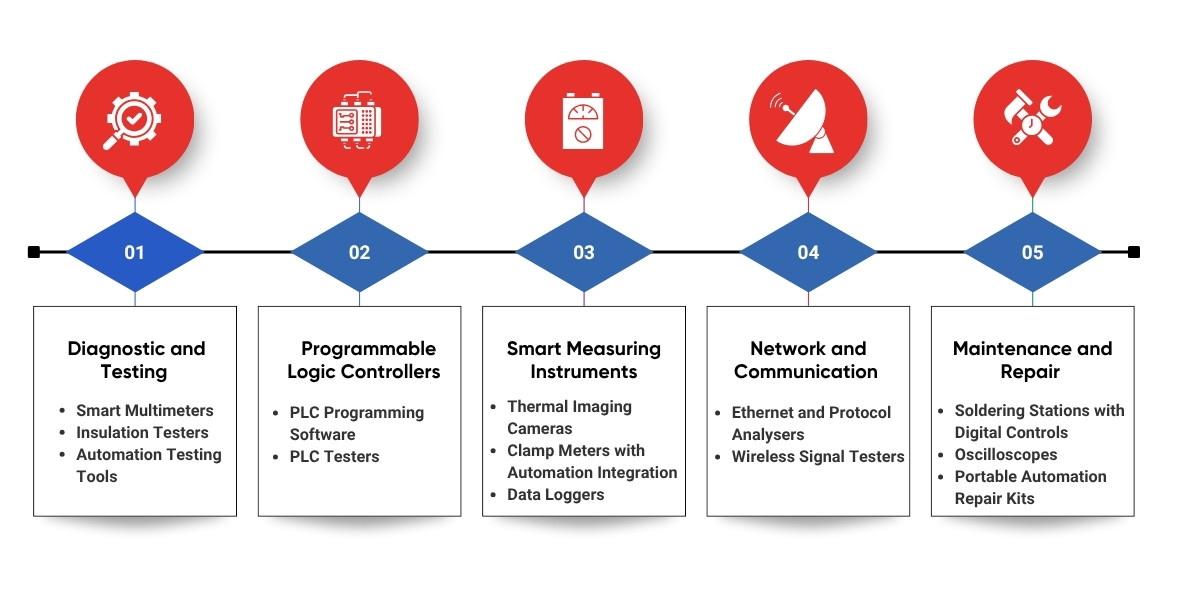

Best Automation Tools Based on Their Categories

Automation tools span multiple categories, each serving specific purposes. Choosing the right tools allows electricians to perform tasks efficiently, reduce errors, and maintain safety standards. Below are some of the key types every electrician should consider:

1. Diagnostic and Testing Tools

Electrical systems can be complex, and troubleshooting issues requires precise testing instruments. Diagnostic tools are essential for detecting problems before they escalate into serious failures. Some of the most valuable tools in this category include:

Smart Multimeters

Modern multimeters go beyond measuring voltage, current, and resistance. They now offer data logging, wireless connectivity, and integration with mobile apps.

Insulation Testers

Ensuring proper insulation is critical in preventing short circuits, equipment damage, and even fire hazards. Insulation testers measure resistance in wires and components, identifying areas that may degrade over time due to environmental factors like heat, moisture, or vibration.

Automation Testing Tools

Specialised software and hardware solutions allow electricians to test automated systems such as PLCs, smart circuits, and motor controllers. These tools simulate operational conditions, verify responses, and help ensure that control systems perform reliably under different scenarios. They are particularly useful in industrial environments where system failures can halt production.

2. Programmable Logic Controllers (PLC) Tools

PLCs are the backbone of modern industrial automation. To work effectively with them, electricians need specialised tools:

PLC Programming Software

This software enables electricians to configure, monitor, and troubleshoot PLC-based systems. Many advanced applications include real-time simulation and debugging features, allowing technicians to identify faults before systems are fully operational. This proactive approach reduces the risk of equipment failure and downtime.

PLC Testers

Hardware testers verify the functionality of PLC input and output modules. They ensure that sensors, actuators, and relays respond correctly to control signals, which is essential for maintaining smooth industrial operations. PLC testers are often used alongside diagnostic tools to create a comprehensive testing workflow.

3. Smart Measuring Instruments

Precision is key when dealing with automated systems. Smart measuring instruments combine traditional measurement functions with advanced technology, making them critical for modern electricians:

Thermal Imaging Cameras

These cameras detect heat patterns, helping identify overloaded circuits, failing motors, or loose connections before they cause serious problems. In large industrial setups, thermal imaging allows technicians to scan entire panels quickly, saving time and reducing risk.

Clamp Meters with Automation Integration

Clamp meters allow electricians to measure current without disconnecting wires. When integrated with automation testing tools, they can provide real-time data to analyse system performance and detect irregularities in industrial electronics repair processes.

Data Loggers

Data loggers record electrical parameters over extended periods, providing insights into trends such as voltage drops, current spikes, or power consumption patterns. This information helps electricians make informed decisions during maintenance, troubleshooting, or upgrades.

4. Network and Communication Tools

Automation in 2026 increasingly involves interconnected devices and smart systems. Network and communication tools are vital for ensuring smooth operation and troubleshooting connectivity issues:

Ethernet and Protocol Analysers

These tools help diagnose issues in industrial networks, such as misconfigured devices, signal interference, or packet loss. They are essential for technicians working with automated systems that rely on real-time data exchange between controllers, sensors, and actuators.

Wireless Signal Testers

In modern smart buildings or industrial facilities, wireless communication is often used to connect sensors and control units. Signal testers ensure reliable connectivity, helping electricians avoid disruptions in automated processes.

5. Maintenance and Repair Tools

Automation repair requires specialised instruments capable of handling complex circuits safely and effectively:

Soldering Stations with Digital Controls

These provide precise temperature control, essential when repairing sensitive electronics or delicate PCB components. Digital soldering stations reduce the risk of overheating components and ensure reliable repairs.

Oscilloscopes

Oscilloscopes are crucial for analysing signal patterns, detecting noise, and troubleshooting timing issues in automated systems. They allow electricians to visualise waveforms and pinpoint faults in real-time, which is invaluable for industrial electronics repair.

Portable Automation Repair Kits

Designed for fieldwork, these kits include insulated tools, connectors, adapters, and mini testers. Electricians performing industrial electronics repair, whether on-site in factories or in commercial facilities, rely on these kits for safe, efficient troubleshooting and repair.

Additionally, some modern kits now incorporate small handheld diagnostic devices that can test multiple functions simultaneously, from voltage and continuity to protocol compliance. This combination of mobility and versatility is especially useful in large-scale installations where speed and accuracy are critical.

Embracing Automation in Electrical Work

The role of an electrician is expanding beyond traditional wiring tasks. The incorporation of automation tools is no longer optional; it is essential for staying competitive, efficient, and safe. From diagnostic instruments to advanced PLC testing systems, the right tools can transform the way electricians work, making complex systems manageable and ensuring high-quality outcomes.

Investing in these tools not only improves efficiency but also enhances the capability to perform industrial electronics repair effectively, whether in a commercial building, industrial setup, or specialised facility in Dubai. Brands like Horizon Elect Devices continue to provide reliable automation repair solutions that meet the evolving demands of the profession.