How to Test a Gas Detector in Industrial Environments?

Gas detectors play a critical role in protecting people, property, and equipment. They are commonly used in industries, commercial buildings, and even residential spaces to detect the presence of harmful gases. A gas detector is only useful if it works correctly. That is why regular testing is essential. Many accidents happen not because a detector was missing, but because it failed to respond when gas was present.

This guide explains how to test gas detector systems properly, using simple steps that anyone responsible for safety can follow. Whether the detector is fixed or portable, testing ensures it responds quickly and accurately when needed.

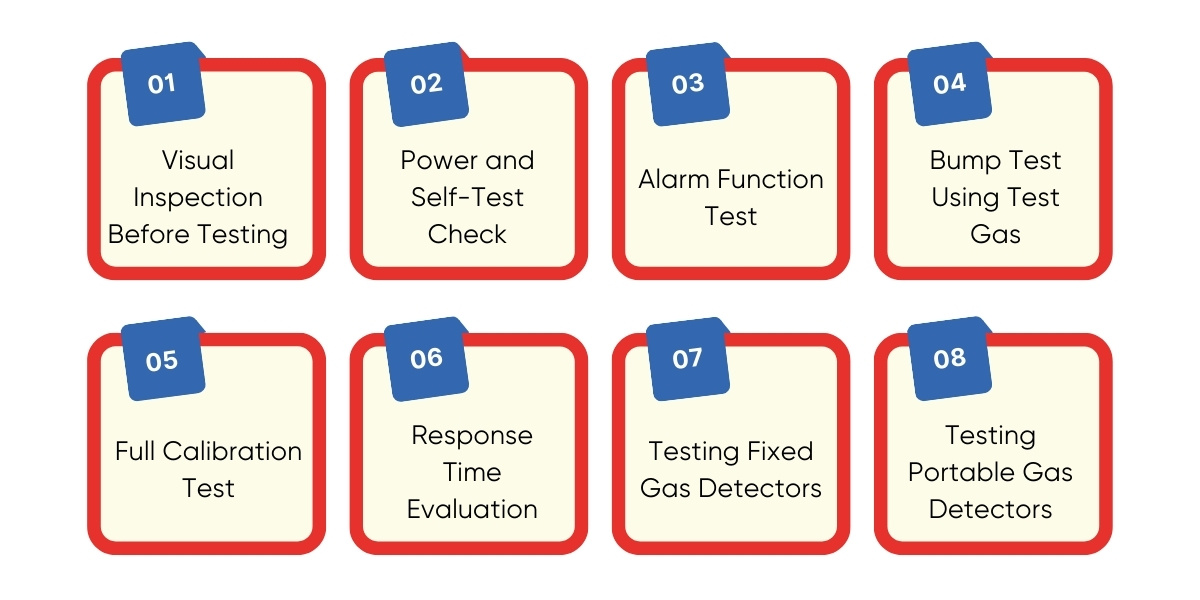

Types of Gas Detector Tests

There are different ways to test a gas detector. Each method checks a specific function of the device. Using more than one method gives better confidence in performance, helping identify hidden faults, sensor drift, alarm failures, and response delays before they create safety risks.

Visual Inspection Before Testing

Before applying any gas or starting electronic checks, begin with a visual inspection.

Look for physical damage such as cracks, corrosion, or loose connections. Check whether the sensor opening is blocked by dust, grease, or paint. Make sure the detector is mounted in the correct location and direction, as per manufacturer instructions. Verify that cables, power supplies, and display screens are in good condition.

If the detector looks damaged or heavily contaminated, testing alone may not be enough. Cleaning or repair may be required before continuing.

Power and Self-Test Check

Most modern gas detectors have a built-in self-test function. This test checks internal electronics, battery level, and basic system health.

Turn on the device and observe startup indicators. Confirm that the display works properly and that no fault codes are shown. If the detector runs on batteries, check battery status and replace weak batteries before further testing.

This step does not confirm gas sensing accuracy, but it ensures the device is powered and operational.

Alarm Function Test

An alarm test verifies that audible and visual alerts are working.

Many detectors include a test button. Press and hold the button as instructed. The alarm should activate immediately, producing sound and flashing lights. If the detector is connected to a control panel, confirm that the alarm signal is received correctly.

This test checks warning systems only. It does not confirm that the sensor can detect gas.

Bump Test Using Test Gas

A bump test is one of the most important steps when learning how to test gas detector accuracy.

A bump test involves exposing the detector sensor to a known concentration of test gas for a short time. The goal is to confirm that the sensor responds and triggers an alarm.

To perform a bump test:

- Use certified test gas that matches the detector type

- Attach the gas cylinder to a regulator and test cap.

- Apply gas briefly to the sensor.

- Observe whether the detector responds within seconds.

The alarm should activate, and the reading should rise above the set alarm limit. If the detector does not respond, it may need calibration or industrial instruments repair.

A bump test is not calibration. It only confirms a basic response.

Full Calibration Test

Calibration is a more detailed process that adjusts the detector to ensure accurate readings.

During calibration:

- The detector is exposed to zero gas or clean air

- Then exposed to a known gas concentration.n

- The device is adjusted to match the correct value.

Calibration should be done according to the manufacturer’s guidelines. Some detectors require calibration every few months, while others need it less frequently.

Improper calibration can cause false alarms or missed gas leaks, so this process should be handled carefully.

Response Time Evaluation

Response time is how quickly the detector senses gas and activates an alarm.

When applying test gas, note how long it takes for the detector to react. Slow response may indicate sensor ageing or contamination. In environments where gas leaks can spread rapidly, a delayed response can be dangerous.

If response time exceeds recommended limits, servicing may be necessary.

Testing Fixed Gas Detectors

Fixed gas detectors are usually installed on walls, ceilings, or near equipment. Testing these units may require access equipment and safety permits.

Ensure the gas reaches the sensor properly. Use test caps designed for fixed detectors. After testing, confirm that alarms reset correctly and that signals clear from the control system.

Fixed detectors are often part of larger safety networks, so testing should include communication checks.

Testing Portable Gas Detectors

Portable gas detectors are commonly used by technicians and field workers.

In addition to sensor testing, check:

- Battery charging and runtime

- Display visibility

- Button response

- Clip or casing condition

Portable units should be tested more frequently since they are exposed to rough handling and varying environments.

Why Gas Detector Testing is Important?

Gas detectors are designed to sense dangerous gases such as methane, carbon monoxide, hydrogen sulfide, or other toxic or combustible gases. Over time, sensors can drift, become contaminated, or lose sensitivity. Environmental conditions like dust, humidity, heat, and vibration can also affect performance.

Testing helps confirm that the detector can:

- Sense gas correctly.

- Trigger alarms at the right concentration.

- Send signals to control panels or safety systems.

- Warn people in time to take action.

Without testing, there is no guarantee that the detector will function during an emergency.

How Often Should Gas Detectors Be Tested?

Testing frequency depends on usage, environment, and manufacturer recommendations.

In general:

- Bump tests may be done weekly or before use.

- Alarm tests can be done monthly.

- Calibration is often required every 3 to 6 months.

- Harsh industrial environments may require more frequent checks.

Ensuring Safety Through Proper Gas Detector Testing

Understanding how to test gas detector systems correctly is essential for maintaining a safe working environment. Testing ensures that detectors respond quickly, alarms function properly, and readings remain accurate over time.

Regular inspection, alarm testing, bump testing, and calibration work together to keep gas detection systems reliable. Skipping any of these steps increases risk and reduces protection.

Companies handling safety equipment in demanding environments, including industrial electronics repair Dubai services, often follow strict testing standards to ensure compliance and reliability. Providers like Horizon Elect Devices typically handle such evaluations as part of broader safety maintenance programs.