How to Inspect Solar Panels for Better Performance?

Solar panels are built to last for many years, but they still need regular inspection to work at their best. Dust, weather changes, wiring issues, or small physical damage can slowly reduce performance if not noticed early. A proper inspection does not always require advanced tools or expert knowledge. With a clear and simple checklist, you can identify common issues before they turn into costly problems.

This guide explains how to inspect solar panels step by step in a practical and easy way. Whether the system is installed on a rooftop or at a ground-level site, these checks help maintain safety, efficiency, and long-term reliability.

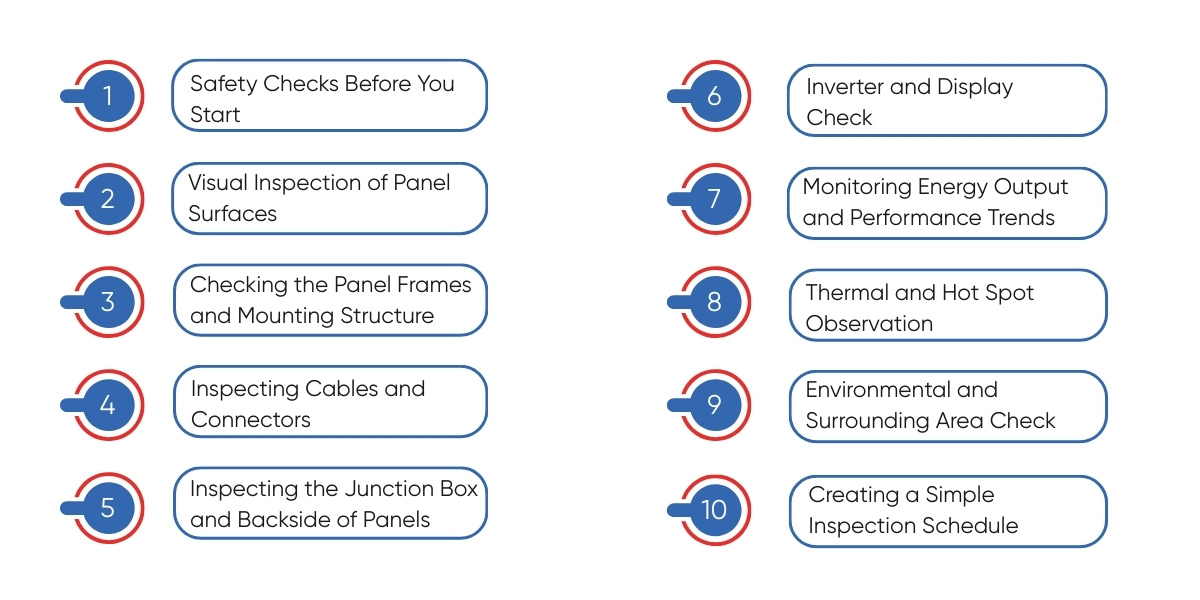

Solar Panel Inspection Checklist for Safe and Efficient Performance

A solar panel inspection checklist helps you examine panels in a clear, step-by-step manner without missing important details. By following this checklist, you can quickly identify visible damage, wiring issues, or performance changes and take timely action to keep your solar system working efficiently and safely.

Safety Checks Before You Start

Before beginning any inspection, safety should come first. Always inspect panels during daylight hours with dry weather conditions. Avoid walking directly on panels, as this can cause cracks or internal damage. If the panels are on a roof, ensure stable access and proper safety equipment.

Switch off the system if you plan to inspect wiring closely. Never touch exposed cables or connectors with your bare hands. If something looks unsafe or unfamiliar, it is better to stop and seek professional help rather than take risks.

Visual Inspection of Panel Surfaces

Start by checking the surface of each panel. Look for visible cracks, chips, or scratches on the glass. Even small cracks can allow moisture inside, which may damage internal cells over time.

Check for discolouration or dark spots. These can indicate overheating or internal cell damage. Also, look for signs of dirt buildup, such as dust, bird droppings, leaves, or pollution residue. Clean panels gently with water and a soft cloth if needed.

Inspect for shading from nearby trees, antennas, or new structures. Even partial shade on one panel can reduce output for the entire string.

Checking the Panel Frames and Mounting Structure

Next, inspect the frames around the panels. Look for corrosion, bending, or loose screws. The mounting structure should be firm and stable, with no movement when lightly touched.

Check whether the panels are still aligned correctly. Panels that have shifted due to strong wind or poor installation may not receive optimal sunlight. Also, inspect the roof or ground base for cracks or water leakage around mounting points.

A strong and secure mounting system protects panels from vibration and long-term mechanical stress.

Inspecting Cables and Connectors

Cables play a crucial role in transferring power from panels to the inverter. Check all visible cables for cuts, cracks, or signs of wear. Look for insulation damage caused by heat, animals, or weather exposure.

Ensure connectors are tightly secured and free from dust or corrosion. Loose connections can lead to power loss or overheating. Pay attention to cable routing and confirm that wires are not hanging loosely or rubbing against sharp edges.

Any damaged wiring should be addressed early, as electrical issues often lead to the need for solar panel repair if ignored.

Inspecting the Junction Box and Backside of Panels

The junction box is usually located on the backside of the panel. Check that it is firmly attached and sealed properly. Look for signs of water entry, burn marks, or melted plastic.

The backside of panels should be free from cracks, moisture stains, or swelling. These issues may indicate internal damage that affects performance. While this area is often overlooked, it is an important part of a complete inspection process.

Inverter and Display Check

Although the focus is on panels, the inverter provides valuable performance information. Check the inverter display for warning lights, error messages, or unusual readings.

Compare current output values with previous records or expected performance based on sunlight conditions. Sudden drops in output may point to panel-level issues, wiring faults, or inverter problems.

Some faults may appear similar to issues seen in power supply repair systems, where voltage instability or component failure affects overall performance.

Monitoring Energy Output and Performance Trends

Regular monitoring helps identify hidden problems that visual checks may miss. Review daily, weekly, or monthly energy production data. If output drops without a clear reason, such as cloudy weather, further inspection is needed.

Compare performance across different panel strings if available. One underperforming section can signal a faulty panel or connection. Consistent monitoring supports preventive maintenance and reduces long-term risks.

Thermal and Hot Spot Observation

If possible, observe panels during peak sunlight hours. Uneven heating or very hot spots may indicate internal cell damage. These areas can sometimes be felt carefully without direct contact or detected using thermal tools.

Hot spots reduce efficiency and can worsen over time. Early detection helps avoid more serious damage to the panel structure.

Environmental and Surrounding Area Check

Inspect the surrounding area around the panels. Remove leaves, debris, or nesting materials that may collect under or around the system. Check for signs of birds or rodents that could damage wiring.

Ensure proper airflow around panels. Poor ventilation can increase operating temperature and reduce lifespan. Environmental cleanliness supports stable and efficient operation.

Creating a Simple Inspection Schedule

A simple schedule makes inspection easier and more effective. Basic visual checks can be done monthly, while detailed inspections can be carried out every six months. After storms or extreme weather, an extra inspection is recommended.

Using a written checklist ensures no step is missed. This structured approach is especially helpful for commercial systems that rely on industrial electronics repair Dubai services when complex faults arise.

Why is Regular Solar Panel Inspection Important?

Solar panels are exposed to sunlight, heat, rain, wind, and dust throughout the year. Over time, these elements can affect panel surfaces, mounting structures, and electrical connections. Regular inspection helps detect early signs of wear, loose parts, or performance drops.

Inspection also improves energy output. Even a thin layer of dirt or a small shadow can reduce efficiency. By following a solar panel inspection checklist, you can ensure that the system continues producing power as expected and avoid unexpected shutdowns.

Ensuring Long-Term Performance Through Inspection

Inspecting solar panels does not need to be complicated. With a clear checklist and regular attention, many common issues can be identified early. Visual checks, cable inspection, performance monitoring, and environmental awareness together form a reliable inspection routine.

Companies like Horizon Elect Devices handle complex inspection and repair work for solar systems and related electronics. Timely expert support can prevent small issues from becoming system-wide failures, similar to preventive practices used in industrial electronics repair environments.