Different PCB Coating Types Used in Today’s Devices

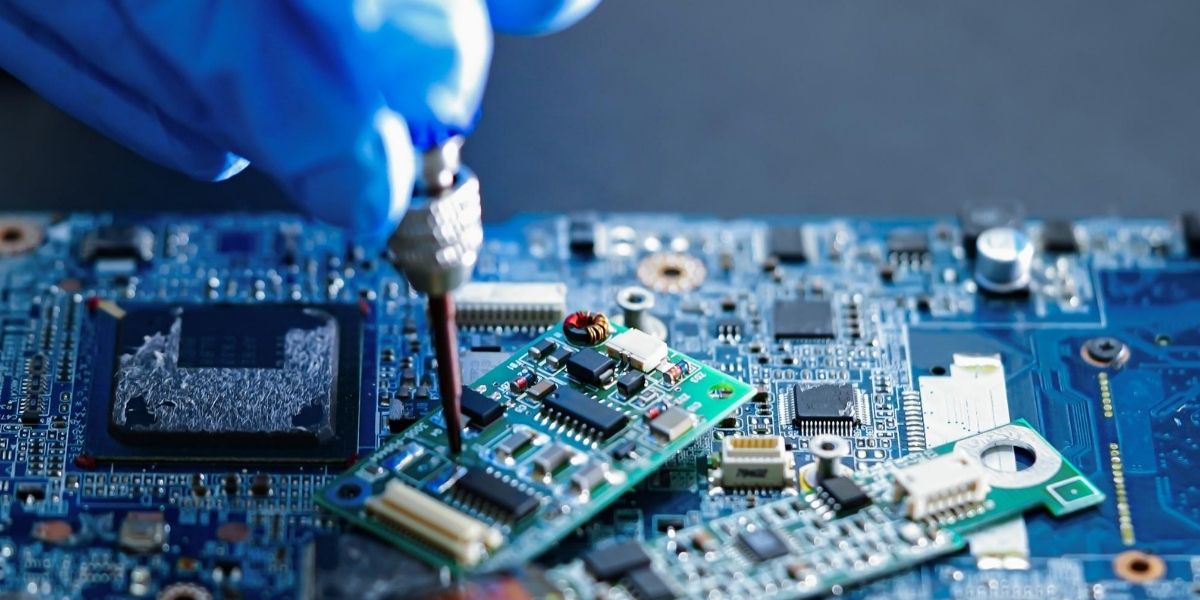

Protecting electronic circuits has become more important than ever as devices continue to get smaller, faster, and more sensitive. Printed circuit boards face constant exposure to moisture, dust, heat, and chemicals, which can weaken performance over time. To reduce these risks, manufacturers apply different protective layers that help increase durability and reliability. These layers are known as coating methods, and understanding them is useful for anyone working with maintenance, troubleshooting, or PCB board repair. This blog explains the most common PCB coating types used today, how they work, and why they matter for modern devices.

Most Effective PCB Coating Types for Reliable Electronics

A proper coating helps reduce damage by creating a thin, invisible barrier over the board. It adds strength, improves resistance to stress, and keeps the device running smoothly. Without this layer, even small environmental changes can lead to bigger failures later.

Here is a complete overview of coating solutions used to shield PCBs from harsh environments. These materials help maintain stability, reliability, and long-term performance.

Acrylic Coating

Acrylic is one of the most widely used coating solutions. It offers a strong level of protection while being easy to apply and remove. This type of coating protects circuits from moisture and dust, making it suitable for devices used indoors or in controlled environments.

Acrylic layers dry quickly and have a smooth finish. They can also be removed easily if maintenance or component replacement is required later. This helps technicians carry out industrial electronics repairs without damaging nearby parts. It is a common choice for consumer electronics, household appliances, and basic machinery.

Silicone Coating

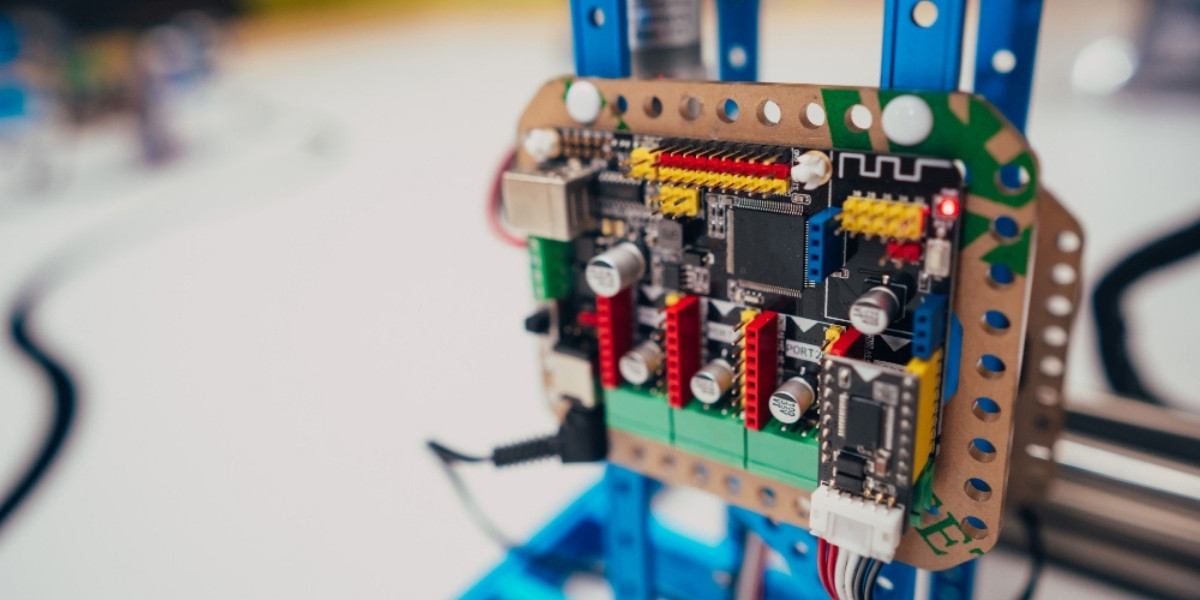

Silicone coating is known for its excellent resistance to extreme temperatures. It performs well in both very hot and very cold conditions, making it popular for outdoor devices and industrial machines. It is also flexible, which helps the board handle vibration, movement, and sudden thermal changes.

This coating works well in environments with high humidity, high heat, or chemical exposure. Many industries use it for power equipment, automotive systems, and lighting products. Since silicone remains stable for long periods, it is a good choice for boards that need to last many years with minimal maintenance.

Polyurethane Coating

Polyurethane is a stronger and more durable option compared to acrylic. It offers protection against moisture, solvents, and chemicals, which makes it suitable for harsher industrial applications. Devices that operate around fuels, oils, or chemical vapours often rely on this type of coating.

One of its biggest advantages is its ability to resist corrosion. Once applied, polyurethane forms a hard, protective layer that shields the board from harsh surroundings. However, it is harder to remove during maintenance, so technicians need special tools and extra care when working on boards coated with this material.

Epoxy Coating

Epoxy is one of the toughest PCB conformal coating types used in modern electronics. It forms a strong, rigid layer that protects circuits from impact, abrasion, chemicals, and moisture. This coating is often used for boards placed in demanding environments, such as industrial machinery or heavy-duty electrical systems.

Epoxy coating offers long-lasting strength but has a downside. Since it forms a rigid layer, it can make repairs difficult. Boards with this coating usually require advanced tools or expert support for even the smallest fixes. Still, its protection level makes it a preferred choice for critical applications where reliability is important.

Parylene Coating

Parylene coating is applied differently from other methods. Instead of brushing or spraying, it is placed inside a vacuum chamber and deposited as a thin film. This unique process ensures an even layer around every corner of the board, including small spaces that other coating types may miss.

Parylene performs extremely well against moisture, corrosion, and chemicals. It is used in medical devices, aerospace systems, and high-precision electronics. Since it is very thin, it does not affect the weight or size of the board. Although the process is more expensive, it is chosen for applications that need very high reliability.

UV Cure Coating

As the name suggests, UV-cure coating hardens when exposed to ultraviolet light. This process speeds up production, which is helpful for manufacturers producing large quantities of devices. UV coatings offer good resistance to moisture, dust, and chemicals.

These coatings are used in both consumer and industrial electronics. They are popular for medium-level protection and fast production cycles. While they offer solid performance, they may require special curing equipment.

Nano Coating

Nano coating uses very tiny particles to form an invisible protective layer on the board. It offers strong resistance to moisture and provides excellent insulation. Unlike thicker coatings, nano coating does not add much weight or thickness, making it ideal for compact electronics.

It is used in smartphones, wearable devices, communication tools, and other lightweight gadgets. Since it can be applied easily and dries fast, it is also becoming popular in several manufacturing industries.

Important Conclusions on Coating Choices

As electronics continue to evolve, coating methods will play an important role in keeping devices safe and efficient. Understanding these layers helps users, technicians, and businesses make better decisions for protection and maintenance. From acrylic to parylene, every method serves a purpose based on the device’s needs and operating environment. With the right coating in place, the lifespan of a board increases and the risk of failure drops significantly.

Whether you are handling new devices or working on PCB repair, knowing these coating methods helps ensure smooth, dependable performance in any application. Reliable support from Horizon Elect Devices also helps businesses maintain long-term stability and protection for their electronic systems.