How to Perform Preventive Maintenance on Industrial Electronics?

In fast-paced industrial environments, keeping equipment running is non-negotiable. Yet many industries wait for failure before acting. Preventive maintenance can extend the life of your electronic devices and equipment and avoid unexpected breakdowns.

What Is Preventive Maintenance?

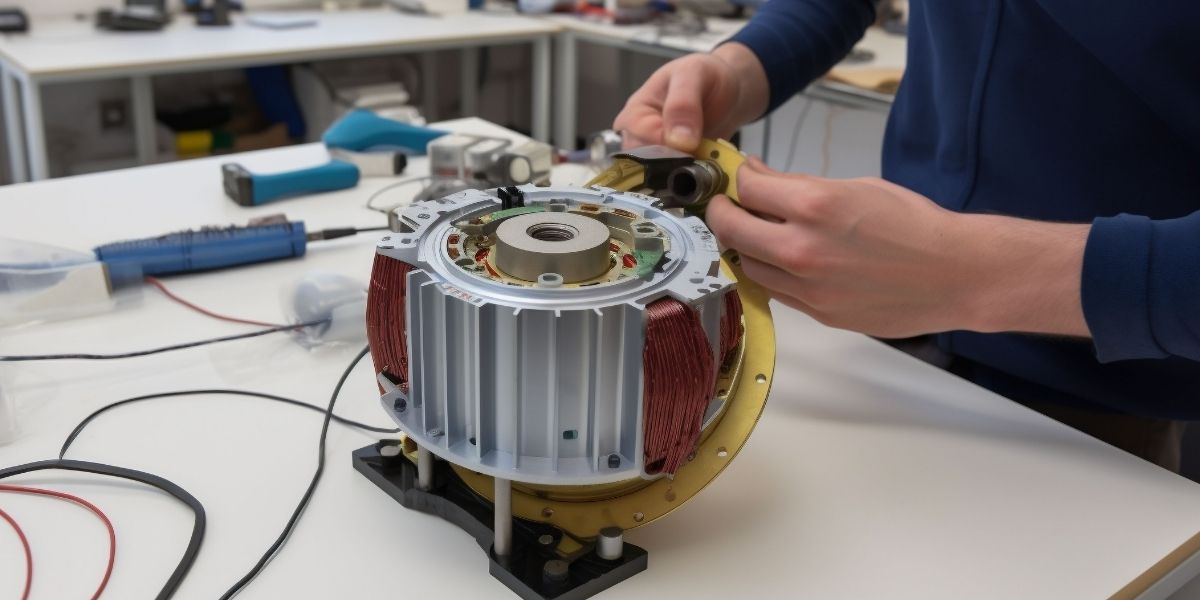

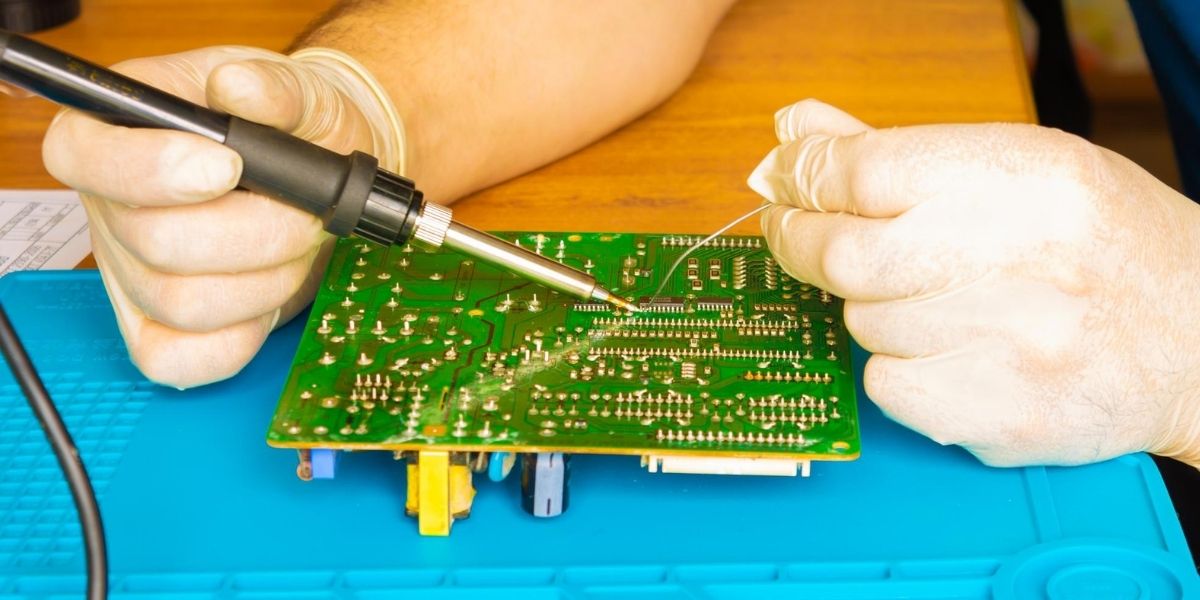

Preventive maintenance is the regular inspection, testing, cleaning, and calibration of industrial electronic components like drives, PLCs, HMIs, power supplies, and sensors, before they fail.

Pros of Preventive Maintenance:

- Increases the lifespan of the device: Identifying issues early prevents major component failures.

- Device come to halt less frequently: maintenance schedules avoid unplanned halts in production.

- Low cost in the long run: Repairing minor faults is far cheaper than replacing full units.

- Safety is improved: Well-maintained equipment reduces the risk of electrical faults and hazards.

Maintenance Activities:

- Dust and debris cleaning

- Checking for loose connections or corroded terminals

- Inspecting capacitors and power modules

- Firmware and software health checks

- Functionality testing under load conditions

Looking for Preventive Maintenance?

At Horizon, we offer modernisation, and preventive maintenance to keep your industrial systems reliable and efficient. We are known in the industry for the minimal callback for our services.